This kitchen towel paper making production line includes the following machines:

This kitchen towel paper making production line includes the following machines:

Features of Glue Laminated Kitchen Towel Paper Making Machine (Middle Level):

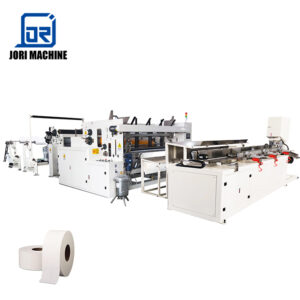

Automatic High-Speed Toilet Paper/ Maxi Roll Rewinding Machine is for toilet paper roll/maxi roll processing.

The machine has a core feeding unit and can do both with and without the core. Raw material from the jumbo roll after full embossing or edge embossing, then perforation, end cutting, and spray the tail glue become a log. Then it can work with cutting machine and packing machine to become the finished products. The machine is controlled by PLC, people operate it through the touch screen, the whole process is automatic, easy to operate, lowers the man cost. And Our machine can be special-made according to clients’ requirements.

Function of Glue Laminated Kitchen Towel Paper Making Machine (Middle Level):

Specification of Glue Laminated Kitchen Towel Paper Making Machine (Middle Level):

| Model | 1500B | 2000B | 2350B | 2550B | 2750B | 2950B | 3150B |

| Jumbo Roll Max. width | 1350mm | 1850mm | 2200mm | 2400mm | 2600mm | 2800mm | 3000mm |

| Max.Jumbo Roll diameter | Standard φ1100mm unless otherwise specified | ||||||

| Jumbo Roll Standings | 2-3 stands (Pls specify when order) | ||||||

| Jumbo Roll Inner Diameter | Standardφ3”(76.2mm) unless otherwise specified | ||||||

| Data setting | HMI | ||||||

| Programming controller | PLC, touch screen | ||||||

| Operate Speed | 0-230m/min | ||||||

| Finished Log Outer diameter | Φ90-280mm | ||||||

| Finished Log Inner diameter | Φ38-76m | ||||||

| Diameter of finished log control | By Electronic/Air control | ||||||

| Mechanical driving | Driving by Stepless gearbox | ||||||

| Air -system | 3HP air compressor, min. pressure 5kg/cm2pa ( Provide by user) | ||||||

| Main driving | Frequency conversion speed regulation 9KW 380V,50HZ (Refer 2000B) | ||||||

| Glue Laminated Unit | 315mm diameter, steel to rubber | ||||||

| Dimensions | Length 6m x Width 3m x Height 1.7m (Refer 2000B) | ||||||

| Weight | 3-4T (Refer 2000B, depends on the model you have) | ||||||

WhatsApp us